Laboratories

ENERMAT Platform

Development of Materials and Processes for Energy Applications

Laboratories

Development of Materials and Processes for Energy Applications

The ENERMAT laboratory was established in 2014 through a collaboration between the Karlsruhe Institute of Technology (KIT) and EIFER. It is located at the Institute for Chemical Technology and Polymer Chemistry (ITCP) on the KIT Campus South

The key research areas include:

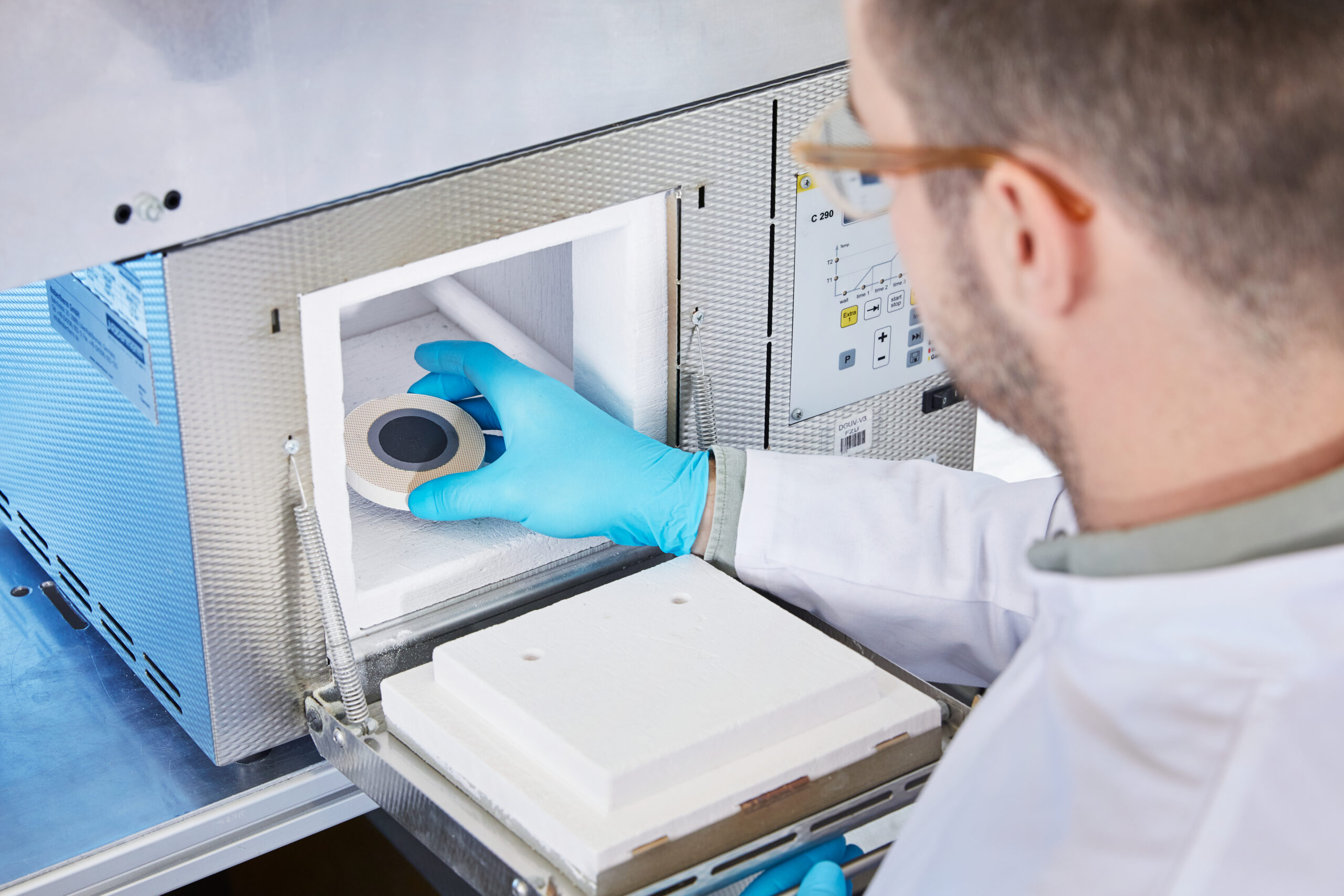

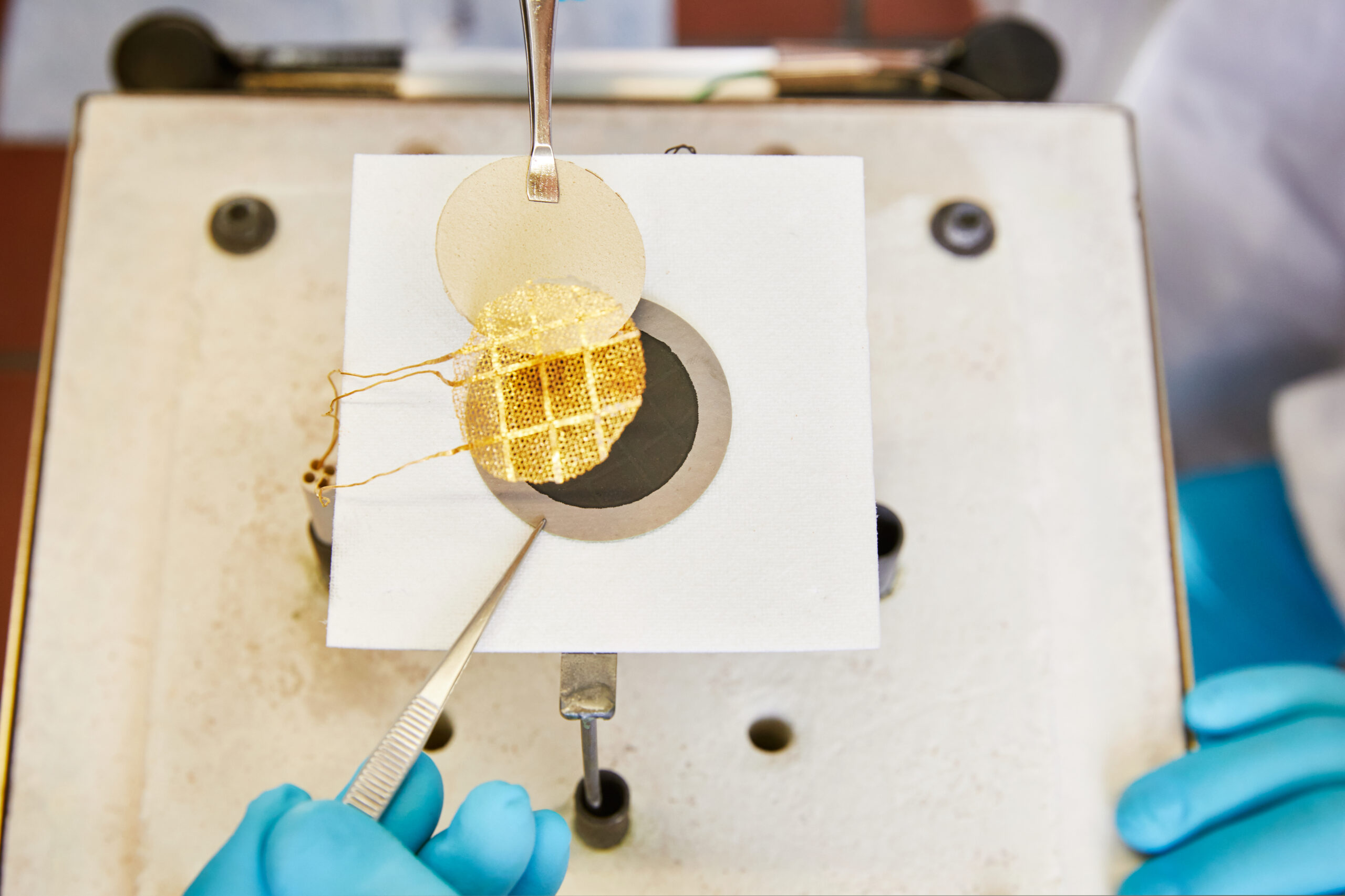

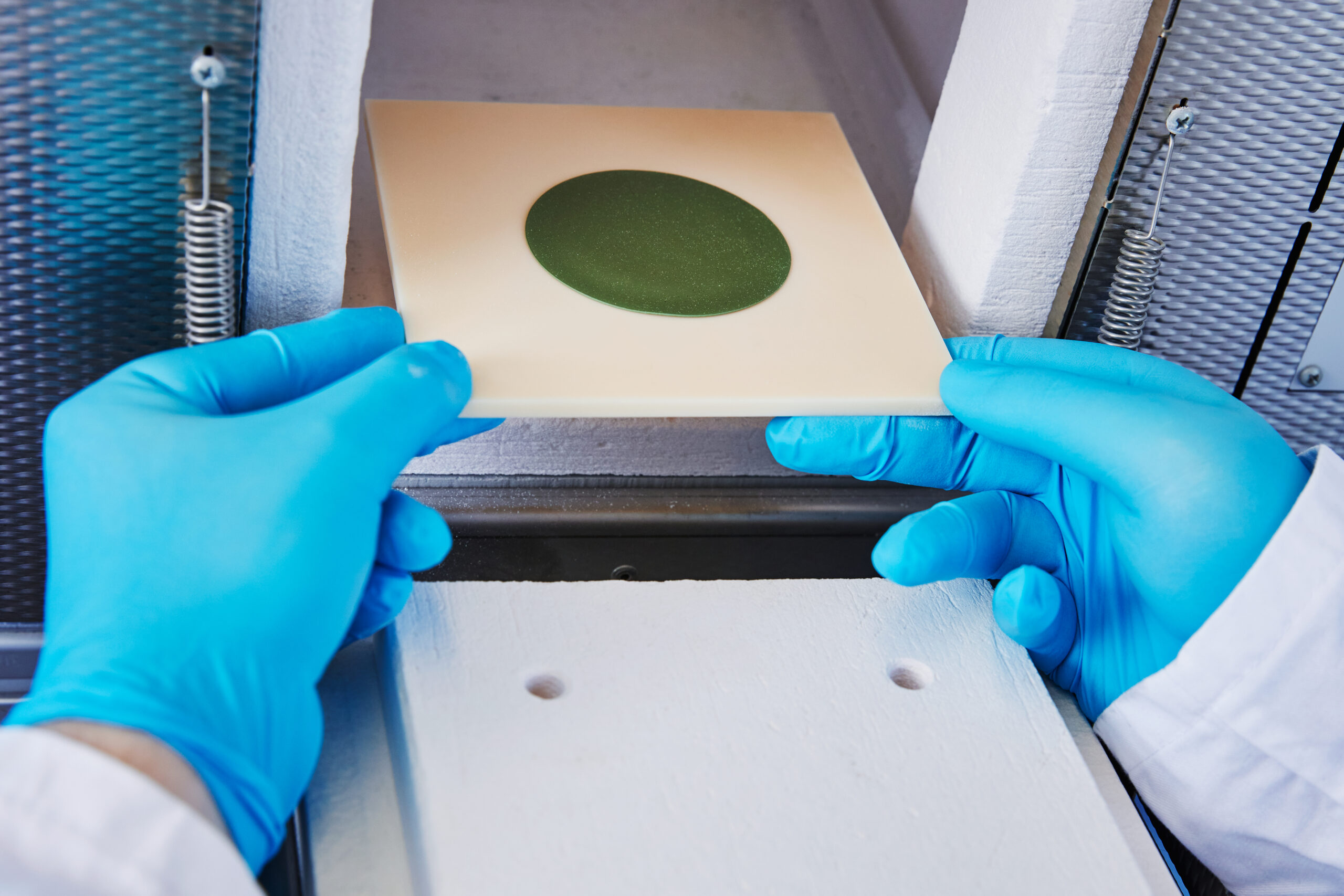

Manufacturing and characterization of innovative powder-metallurgical processed materials, covering the whole production process, from the raw material to the finished product in 3 steps.

ECOMET

HADES

PEPPER

Dr. Julian Dailly